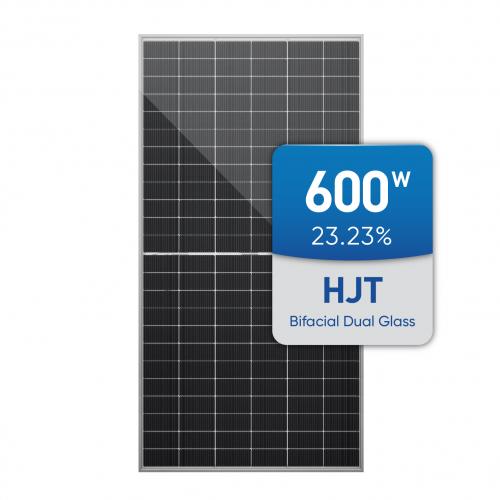

EVO5N 600W Bifacial N-type HJT 144 Cells Solar Module

-

-

-

-

- In stock, ready to ship

- Backordered, shipping soon

EVO 5N N-type HJT 144 Half Cells 600W Bifacial Dual Glass Solar Module

EVO 5N Series Bifacial modules combine combining gettering process and single-side μc-Si technology to ensure higher cell efficiency and higher module power. More stable power generation performance and is even better in hot climates. Natural symmetrical bifacial structure brings more energy yield from the backside.

Electrical Parameters (STC*)

|

Maximum Power (Pmax/W) |

580 |

585 |

590 |

595 |

600 |

|

Maximum Power Voltage (Vmp/V) |

45.00 |

45.21 |

45.42 |

45.63 |

45.84 |

|

Maximum Power Current (Imp/A) |

12.89 |

12.94 |

12.99 |

13.04 |

13.09 |

|

Open Circuit Voltage (Voc/V) |

53.92 |

54.12 |

54.31 |

54.50 |

54.70 |

|

Short Circuit Current (Isc/A) |

13.35 |

13.40 |

13.45 |

13.50 |

13.55 |

|

Module Efficiency (%) |

22.45 |

22.65 |

22.84 |

23.03 |

23.23 |

|

Power Output Tolerance (W) |

0/+5W |

||||

|

Temperature Coefficient of Isc |

+0.040%/°C |

||||

|

Temperature Coefficient of Voc |

-0.240%/°C |

||||

|

Temperature Coefficient of Pmax |

-0.260%/°C |

||||

| 5% | Maximum Power (Pmax/W) | 641 | 646 | 652 | 657 | 663 |

| Module Efficiency STC(%) | 23.57 | 23.78 | 23.98 | 24.18 | 24.39 | |

| 15% | Maximum Power (Pmax/W) | 667 | 673 | 679 | 684 | 690 |

| Module Efficiency STC(%) | 25.82 | 26.05 | 26.27 | 26.48 | 26.71 | |

| 25% | Maximum Power (Pmax/W) | 725 | 731 | 738 | 744 | 750 |

| Module Efficiency STC(%) | 28.06 | 28.31 | 28.55 | 28.79 | 29.04 |

1. Technical Difficulties:

10 or 11 steps in the PERC process, such as two lasers, one phosphorus expansion, and double-sided coating;

TOPCon adds silicon dioxide and polysilicon plating process, and boron expansion is required in the front, but there is no laser opening, and there is a wet method;

In fact, HJT only starts from cleaning, double-sided plating of microcrystalline silicon or amorphous silicon, then ITO, and then silk screen sintering. It used to be very simple, only 4 steps, but now silicon wafers still need gettering. It used to be a low-temperature process. into 8 steps.

In fact, the first major difficulty of TOPCon is boron expansion, and the second is LPCVD. Single-side plating and back-winding plating are more serious, and the yield rate is not high.

This problem is basically solved after double-sided expansion, but there are still many problems in LPCVD. The tube wall is plated very quickly. 150nm things are made of 10 furnaces of 1.5um, and the tube wall is quickly plated on the tube wall. The tube wall needs to be cleaned frequently, but the low-pressure process of The LPCVD needs to be laminated requires thick quartz tubes, and needs to be cleaned at the same time, which is a relatively big problem.

Now double casing is used, the outside is laminated, and the inside is coated with a layer of film. It is often taken out for cleaning. Although this is better, it takes some procedures. The so-called operating rate will be affected because maintenance is required.

The actual expansion of the boron itself is a difficult thing. The process steps are relatively long, resulting in relatively large yield loss, and there are some potential problems that may cause yield and production line fluctuations, diffusion burn-through and silver paste burn-through polysilicon film, resulting in passivation damage, and high-temperature processes that cause silicon wafers damage;

One of the difficulties of HJT is that PECVD maintains purification, which is required to be close to the semiconductor process, and the purity requirements are stricter than before TOPCon diffusion. After HJT2.0 and 3.0, because the hydrogen dilution rate increases, the deposition rate needs to be accelerated, and high frequency is introduced, which will lead to uniformity. sex decline.

In addition, there is also the issue of cost, how to reduce the amount of silver paste, and further improve the stability of the battery.

2. Cost difficulty:

Topcon also has pain points, one is the relatively low yield rate, and the other is CTM. The low yield rate increases the cost, and the CTM is relatively low/and the actual component power is significantly different. It is also relatively difficult to improve efficiency, and there is not much room for improvement in the future, because the frequency of equipment maintenance is relatively high; The cost difficulty of HJT is that the slurry consumption is relatively large. One is how to reduce the quantity and how to reduce the price. In addition, the CTM is relatively low. Crystallite preparation requirements are also involved, affecting cost and technology.

3. Crafting process:

Many people asked me to list the cost split. In fact, I don’t think the cost split is very meaningful. You can see that the cost reduction depends on the logic, that is, what logic is used to reduce the cost. Compare these three processes, such as comparing how high the temperature of these three is. PERC has 3 high-temperature processes, one for phosphorus expansion at 850°C, two for coating at 400-450°C, and sintering at 800°C. TOPCon high-temperature processes include boron expansion at 1100-1300°C, phosphorus expansion at 850°C, LPCVD at 700-800°C, two coatings at 450°C, and sintering at 800°C. There are many high-temperature processes, high heat load, high energy consumption, and cost.

It cannot be seen from the investment in materials and equipment, but in fact, from the perspective of electricity bills, it is at least higher than PERC. If HJT does not absorb impurities, it is actually 200°C, PE at 200°C, sintering at 200°C, and PVD at 170°C. So it is very low temperature, and the low temperature time is not long, because the coating time is very short, and it is often coated with a thickness of 2nm, 3nm, and 10nm.

However, the leaching time is relatively long, leaching a carrier board for 8 minutes from the beginning to the end. The amount of a carrier plate is less than that of a tubular PECVD, and the diffusion of tubular PECVD is 2400°C or 1200°C, while a carrier plate 12*12=144 travels faster but the amount is also small.

This is somewhat comparable, in short, the temperature is relatively low. But if fast phosphorus gettering is done, the process can reach 1000°C, but the duration is short, only 1min, and the entire heat load is much lower than TOPCon.

Let's look at the wet process again: PERC is 3 times, TOPCon is 5 times, HJT used to have only one time of texturing without absorbing impurities, and only one piece of equipment, which is very simple. If there is dirt pick up, wash/remove the damage before the getter picks up, there is velvet at the back, and the wet process is very short.

The vacuum process of PERC includes phosphorus expansion and two PECVDs, both of which are also vacuum, but the vacuum degree is relatively low, and a rod pump is enough.

The vacuum degree of TOPCon is relatively high, and phosphorus expansion, boron expansion, LPCVD and PECVD are performed twice each time. The vacuum degree is not high, and 5 times of vacuum rod pump are enough.

There are two HJT processes, one is PECVD and the other is PVD. PVD requires a relatively high degree of vacuum and uses a molecular pump, so this will consume more energy in terms of vacuum requirements.

The entire process depends on the current cost and the future cost reduction process, and the various energy consumption and losses caused by the simple process will be much lower.

- Free Shipping: We offer Free shipping with a delivery time of 3-7 Working days to make your shopping hassle-free.

- In Stock: Our store items are all in stock, ensuring that you can enjoy your favorite items instantly.

- Own Warehouse: Our warehouse is located in Los Angeles, California, ensuring that your order is delivered quickly and on time.

- Returns and exchanges are hassle-free: What's more, returns and exchanges are hassle-free to make your shopping experience easier and more enjoyable.

- 30 days money back guarantee: If you are not satisfied with your item, we will provide you with a money back guarantee within 30 days.

Thank you for your choice and support, and we look forward to providing you with quality logistics services!

More details at Shipping Policy!

If you choose to use the surface mount installation as an option for your fencing, we will not warranty nor will assume liability for the fencing boards or the post/mounting system in the event of wind-related damage.

Standard warranty for color and material integrity will apply, but damage due to wind will be considered an act of nature and as such will not be covered. If you have any questions or concerns about the product before installation, please feel free to contact us.

Solar Systems Depot is a leading distributor of high-quality solar energy products and

solutions. We provide a wide range of solar panels, inverters, batteries, and other solar

accessories to meet the needs of residential, commercial, and industrial clients.

Our main office is located at 40 Wall Street 40 Fl New York NY 10005 We also have several

distribution centers across the country to ensure timely delivery of products.

You can reach us via phone at 888-334-0366 or email info@solarsystemsdepot.com or

through our website's contact form.

We offer a comprehensive range of solar products including solar panels, inverters, batteries,

mounting systems, and monitoring solutions. We also provide complete solar kits for residential

and commercial installations.

Yes, we provide free engineering services to help you design and customize the best solar

system for your needs. Our team of experts will create a layout and provide a free diagram to

ensure optimal performance and efficiency.

While we primarily focus on distribution, we can connect you with certified installers in your

area. Please contact our customer service team for more information.

Yes, all of our products are certified to meet international standards for quality and safety. We

work with reputable manufacturers to ensure the highest quality.

Yes, we offer warranties on all our products. The duration and terms of the warranty vary

depending on the product. Please refer to the specific product's warranty information for details.

Orders can be placed through our website, by phone, or by email. If you need assistance, our

customer service team is available to help you with the ordering process.

Yes, we have a return policy in place. If you are not satisfied with your purchase, you can

return the product within 30 days of receipt. Please refer to our return policy for detailed

instructions and conditions.

Delivery times vary depending on the product and your location. If the item is in stock, you

can expect to receive it within 5-7 business days. However, for most products, we offer a more

cost-effective option by shipping directly from our partner factory to your doorstep, which takes

around 30-40 days on average. This approach allows us to pass significant savings on to you.

The wait is well worth it for the significant cost savings that make it worth it for most customers.

Our order process is straightforward:

Initial Deposit: We require a 35% down payment to secure your order.

Final Settlement: The remaining balance is due 5 days prior to the scheduled delivery date,

ensuring a smooth and convenient process.

We accept various payment methods including credit cards, bank transfers, and PayPal. We

also offer financing options. Please contact our sales team for more details.

Yes, we provide technical support for all our products. Our team of experts is available to

assist you with installation, troubleshooting, and maintenance.

If you are interested in becoming a distributor or reseller, please contact our sales team for

more information on partnership opportunities.

Sustainability is at the core of our business. We ensure that our products are sourced from

manufacturers who adhere to strict environmental standards. Additionally, we are committed to

reducing our carbon footprint through efficient operations and eco-friendly practices